PRODUCTS

Categories

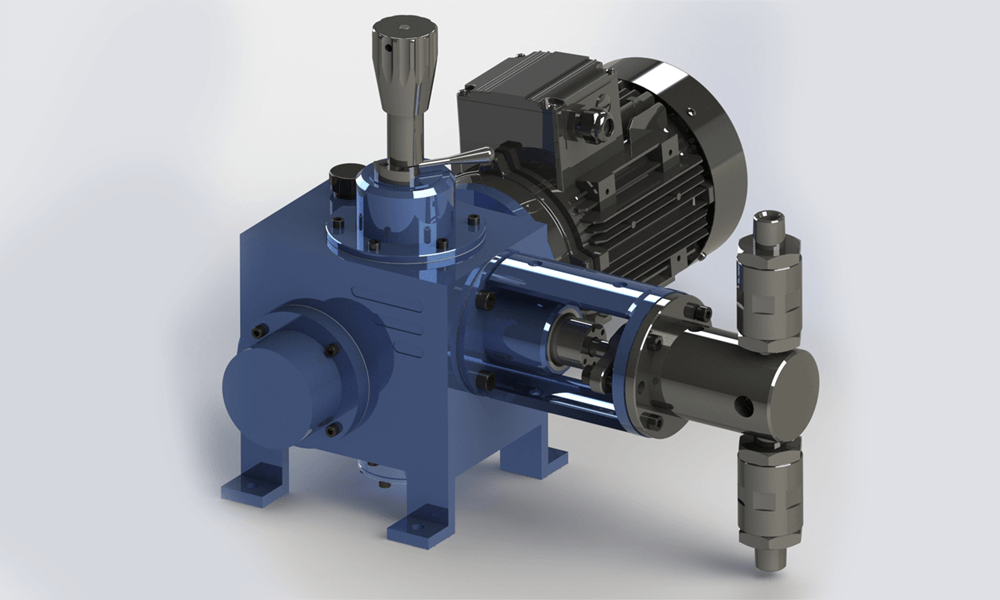

DPA-002

- Flow range: 0-500l/h

- Pressure range 0-500 bar

- Certification number: FIDI19 ATEX D064

DPA-002

- Flow range: 0-500l/h

- Pressure range 0-500 bara

- Certification number: FIDI19 ATEX D064

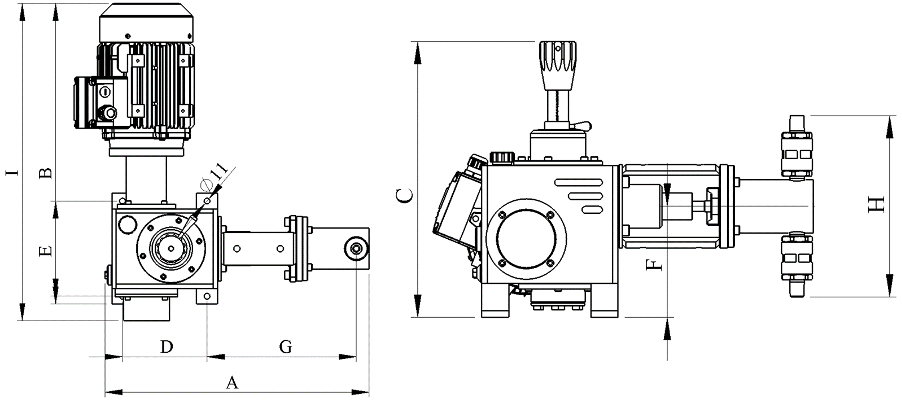

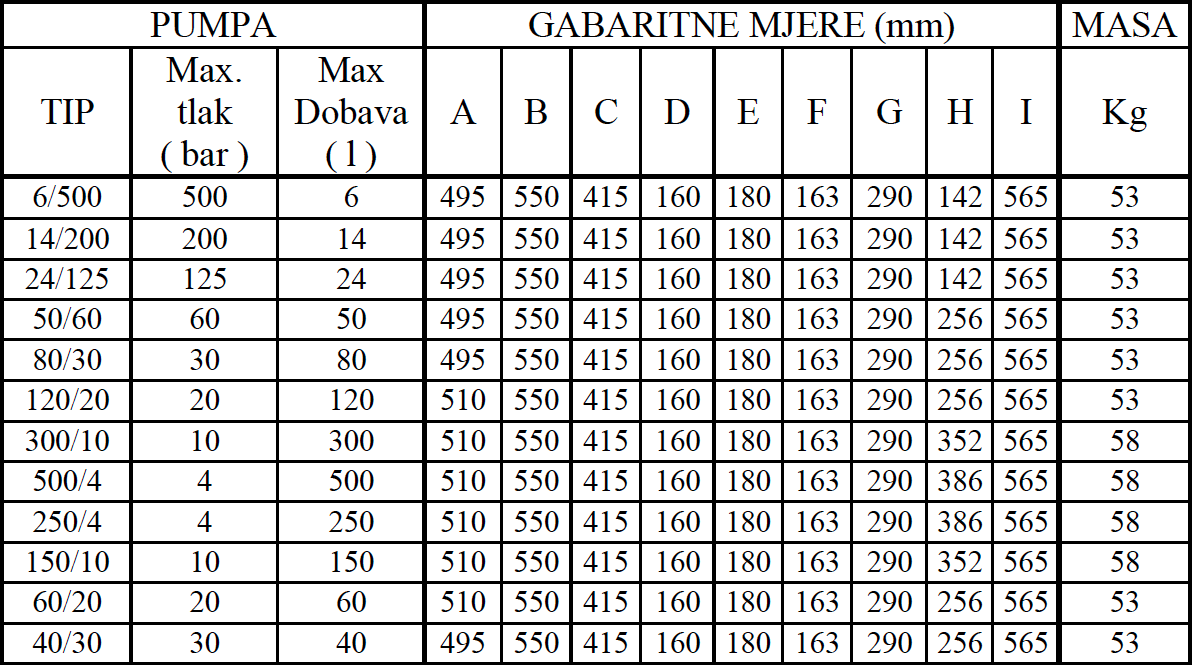

The dosing-pump unit DPA-002 is designed for operation in conditions of pressure up to 500 bars and discharge up to 500 l/h, while DPA-002-2M is designed for pressures up to 200 bar and discharge up to 330 l/h. If the unit works in explosive mixture, the unit can be equipped with an explosion proof electric motor. The very dosing-pump unit has no mobile parts outside the housing, which guarantees operator safety during control or setting working conditions.

Both types are intended for operation in food processing, pharmaceutical, oil and other industry where precise regulation of media dosing is required. The supply regulation is performed by changing the piston stroke length by the regulation screw with vernier divided by 0,25% of maximum supply. The number of strokes is constant.

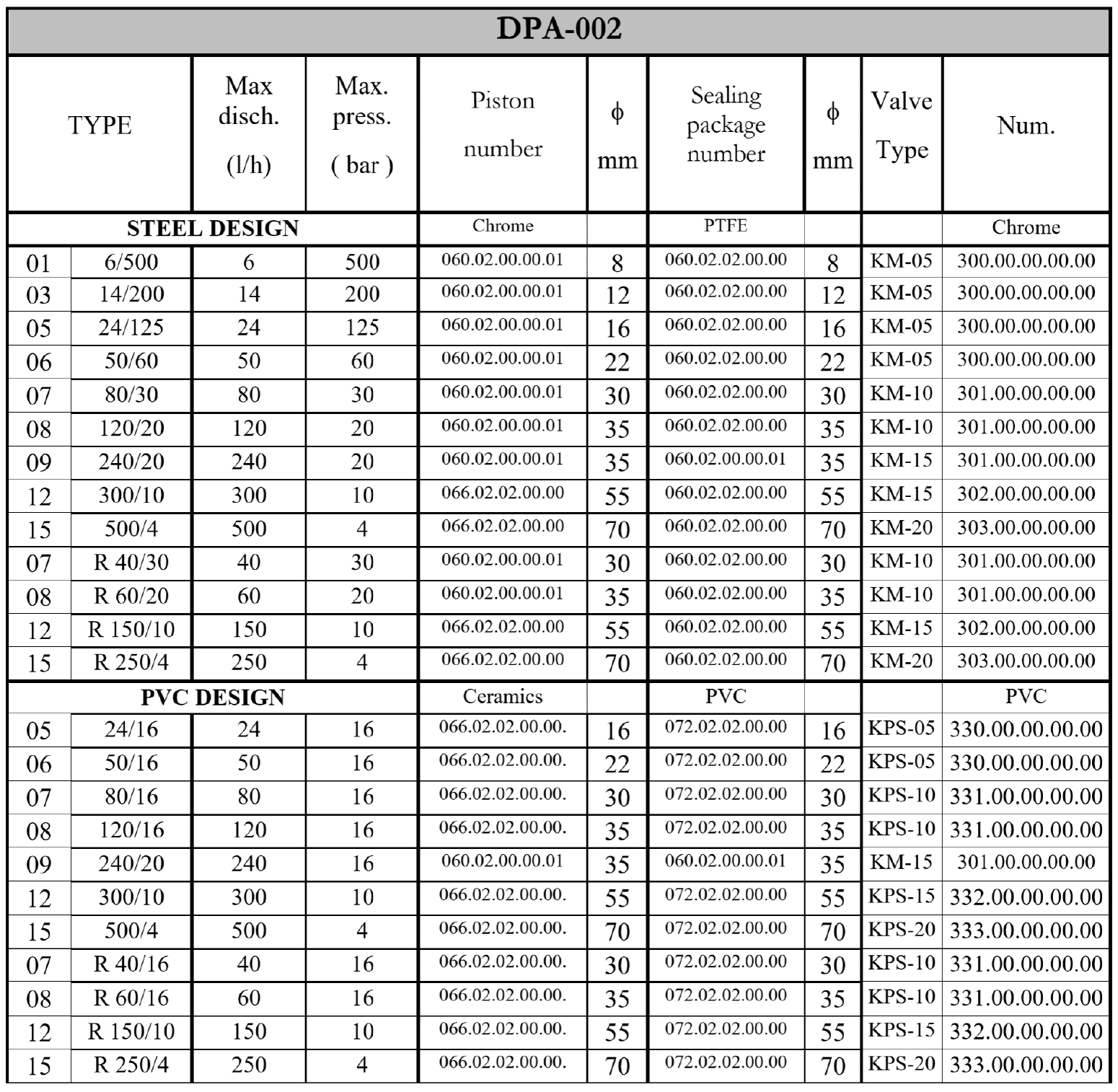

Piston as well as suction and pressure valve are manufactured in metal or non-metal design depending on the type of media for which the pump is intended for.

We manufacture pumps from Stainless steel material for pressures up to 500 bars and 500 l/h. Plastic pumps are manufactured from “PVC” material with a ceramic piston and are intended for aggressive media up to 500 l/h and maximum pressure of 16 bar.

Hydraulic diaphgram dosing pumps are manufactured with 2 diaphragms and equiped with diaphragm rupture indication via pressure gauge on pumps head. These type of pumps are used in varety of situations and are applicable in oil/gas production (onshore/offshore), refineries, and the chemical and petrochemical, pharmaceutical, cosmetic and food production

- Bjelovarska cesta 18, Koprivnica

- Ceo: +385 48/642-519

- Accounting: +385 48/642-439

- Comercial: +385 48/642-439

- Mail: info@duwar.hr