PRODUCTS

Categories

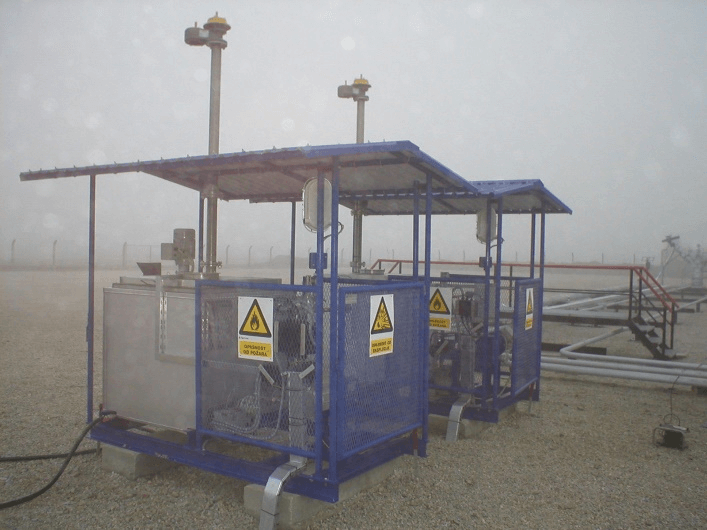

Triethylene glycol injection package unit

- Flow range: 0-1500l/h

- Pressure range 0-800 bar

Triethylene glycol injection package unit

- Flow range: 0-1500l/h

- Pressure range 0-800 bar

This device has been developed to achieve the simple triethylene glycol usage. It represents an independant type unit with quick mounting ability. The dosing-system has its own steel carrier as well as all the other required attachments on the carrier rim. This enables easy mounting at place where used and it can start operating in a very short period of time.

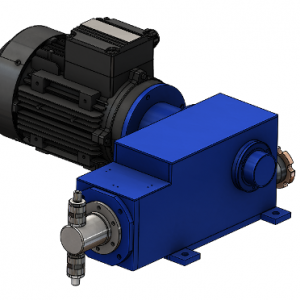

The basis of the corrosion inhibitor injection package unit is constructed of two dosingpump units type DPA-002-14/200 driven by „S“ construction electromotors of N=0,55 kW power and dosing-pump units type DPA-001-21/500 driven by „S“ construction electromotors of N=2,2 kW power. There is also a 2500 l tank on the carrier, which does not have only water level showing glass but also oil opening, drainage opening, breathing valve DN 80, magnetic level switch (type SMK – 4), ultrasonic level transmitter, thermostat, safety thermostat and electrical heater.

The tank is thermally isolated with 50 mm poliuretan and protected with A1 sheet metal in order to lessen the media heating from the surrounding atmosphere.

- Bjelovarska cesta 18, Koprivnica

- Ceo: +385 48/642-519

- Accounting: +385 48/642-439

- Comercial: +385 48/642-439

- Mail: info@duwar.hr